Audi uses AI in production for quality control and automation

Audi implements AI at Neckarsulm plant with EC4P platform, controlling robots and enhancing quality control. Learn about AI-driven innovations in automotive production.

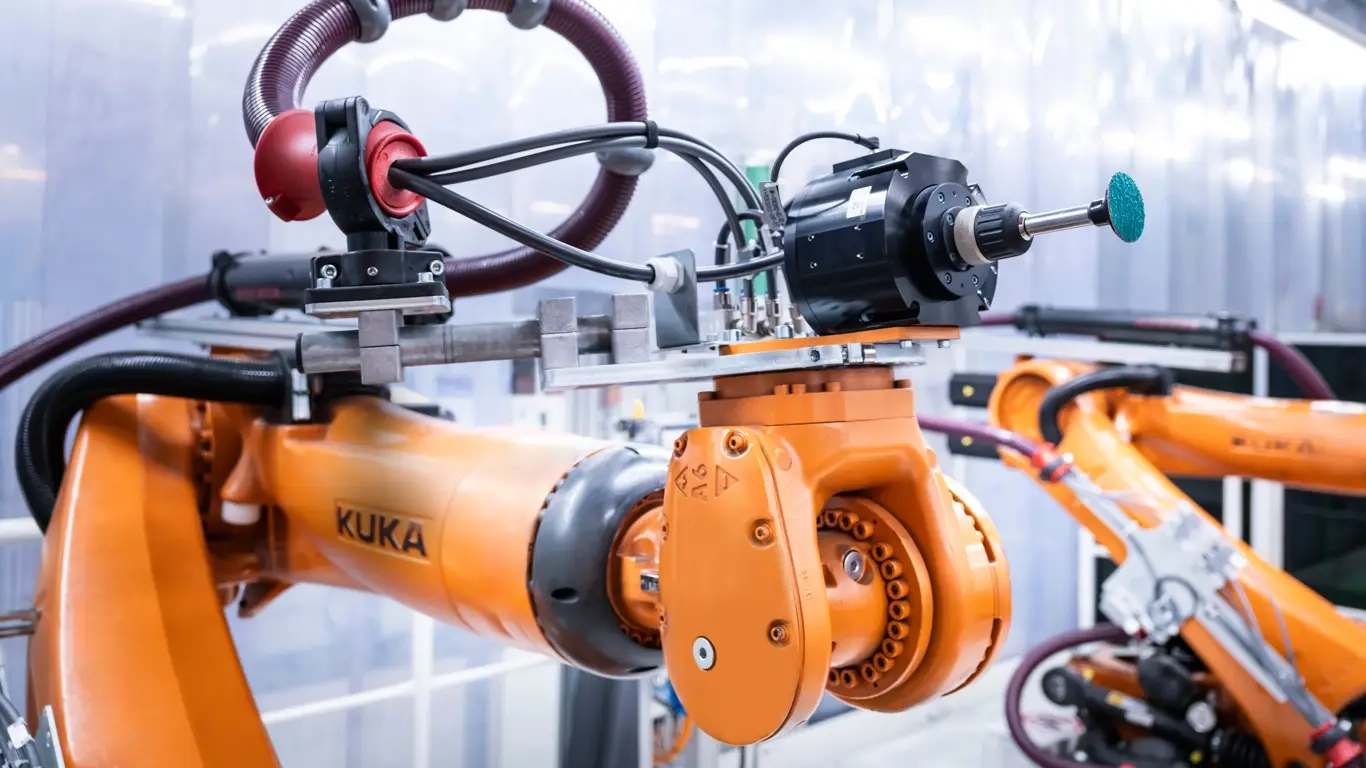

Audi is expanding its use of artificial intelligence in production and logistics. At its Neckarsulm plant, the cloud-based Edge Cloud 4 Production (EC4P) platform already controls around 100 robots in the body shop where the A5 and A6 models are built. This system has replaced local controllers with virtual PLCs and eliminated over 1,000 industrial computers across Audi's German facilities.

In parallel, the company is implementing AI-driven quality control systems. The Weld Splatter Detection solution automatically identifies welding spatter on the vehicle underbody and directs defective areas to robotic processing. Another development, ProcessGuardAIn, is designed to monitor production processes and is currently undergoing pilot testing in the paint shop. Series application is planned for the second quarter of 2026.

Additionally, Audi is participating in the Next2OEM project in Ingolstadt, where it is working with ten partners to develop fully digital and automated production of cable harnesses—one of the least automated processes in the industry.

The company notes that AI is viewed as a key element for improving efficiency and supporting personnel in the production of new vehicles in 2026.