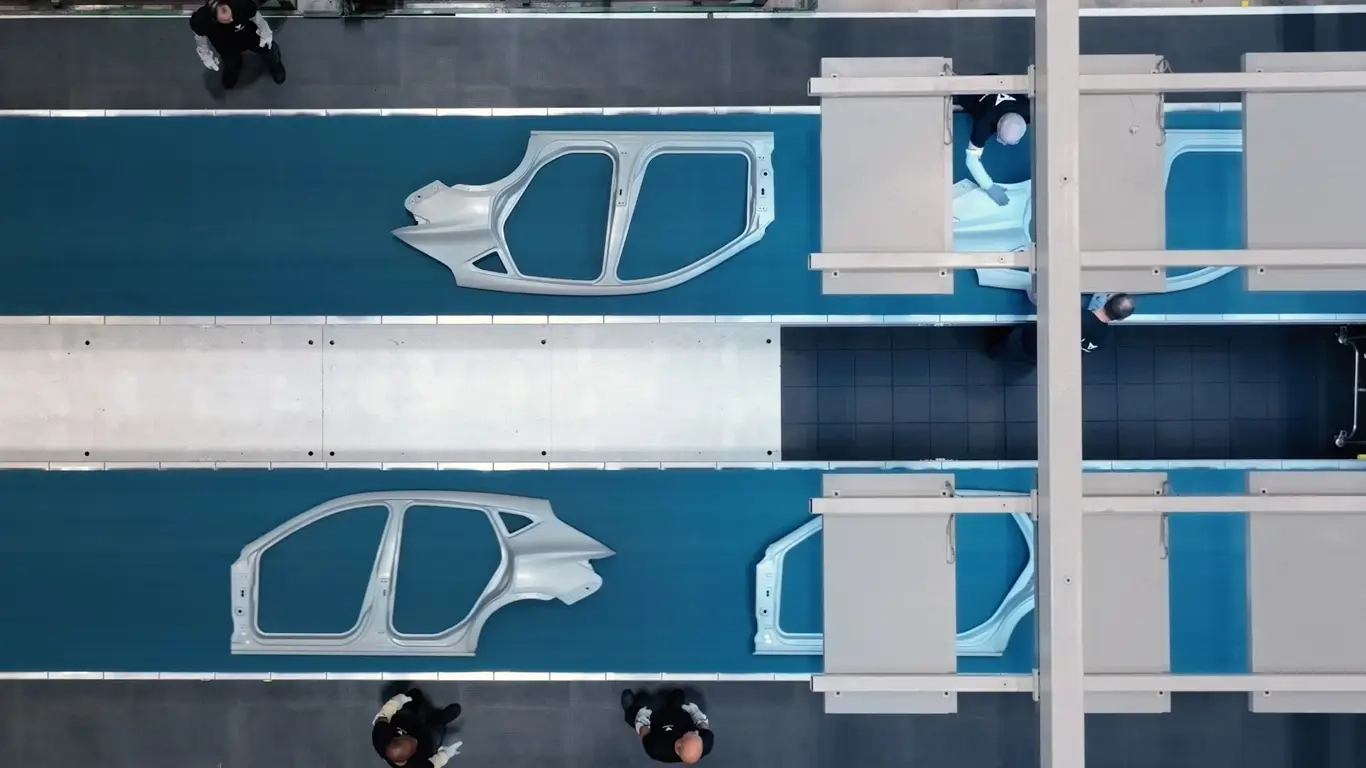

Inside Seat's high-speed PXL press line for Cupra Raval and Volkswagen ID. Polo

Seat's Martorell PXL press line delivers up to 4M body parts/yr, 15 cycles/min and 5-minute changeovers for Cupra Raval and VW ID. Polo, and smart telemetry.

Seat’s Martorell plant has brought a new PXL press line online, a six-machine setup that ranks among the most sophisticated in the world. At full tilt, it can turn out up to four million body components a year. The line will serve the upcoming Cupra Raval and Volkswagen ID. Polo, and it is already feeding parts into current production.

According to the press release, the press runs at up to 15 cycles per minute. Tool changes now take just five minutes, making as many as 15 reconfigurations possible in a single day. Beyond the headline numbers, that cadence frees the factory to switch between parts quickly, trim batch sizes, and respond to demand with far less downtime.

The press structure is rated at 81,000 kilonewtons and anchored on a 20-meter-deep foundation. Each cycle logs roughly 3,000 data points, a level of telemetry that points to tighter process control and earlier detection of issues—exactly the sort of discipline that keeps output consistent and scrap in check.

The launch of the new line forms part of preparations for the 2026 model rollouts, reinforcing the positions of Seat and Cupra in Europe’s electric and compact segments. It’s a timely investment that aligns manufacturing muscle with a market increasingly shaped by efficiency and quick turnarounds.